How (not) to digitalize your plastic injection molding process

Better first-time-right through a better way of working Our whitepaper “HOW (NOT) TO DIGITALIZE YOUR PLASTIC INJECTION MOLDING DESIGN PROCESS”...

.png)

Which material you choose has a significant impact on your costs. The material you initially select is not always the most economical.

The time from closing the mold, to injecting the melt, to cooling the material, to demolding and ejecting is your cycle time. The shorter your cycle time is, the more parts you can produce in the same time. The bottleneck here is usually the cooling time after which the part can be ejected. To minimize the cycle time, you need the part to cool down as quickly as possible.

This may seem obvious, but try to avoid unnecessary complexity in surface structures, whenever possible. Use draft appropriately. Often expensive rework is necessary otherwise. You can also create grip, for example, through other ergonomic shape adjustments. You can even save on something as indispensable as serial numbers: just leave out the serifs.

Areas that can't be demolded in the main demolding direction require sliders, which are very costly. You can save this money, with good part design. You may also be able to use an elastic material to provide a solution for ejection.

Every material shrinks as it cools, and often it warps because it rarely shrinks uniformly. Good mold makers naturally take this into account when building the mold. However, they will not always hit the bull's eye. Then, expensive mold corrections are necessary.

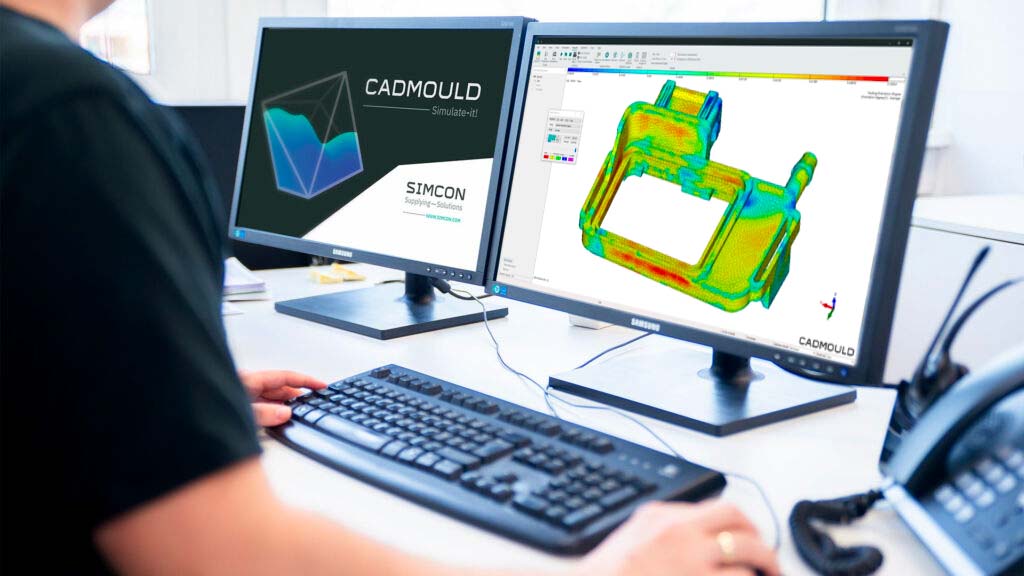

With a good simulation solution, you can optimize the geometry, the gating situation or process parameters in such a way that the warpage is minimized from the start. Although sampling is still necessary, the remaining corrections will usually be more minor, and the number of correction loops is significantly reduced.

Better first-time-right through a better way of working Our whitepaper “HOW (NOT) TO DIGITALIZE YOUR PLASTIC INJECTION MOLDING DESIGN PROCESS”...

Find out what the advantages and disadvantages of plastic injection molding simulation are. Our opinion: if the prerequisites are right, it only...

3 min read

Shanghai, People’s Republic of China, March 18, 2021 Simulation and optimization solutions now available at ZIMMY, China Digital engineering...