Tear down this wall: ARBURG and SIMCON connect simulation and machine

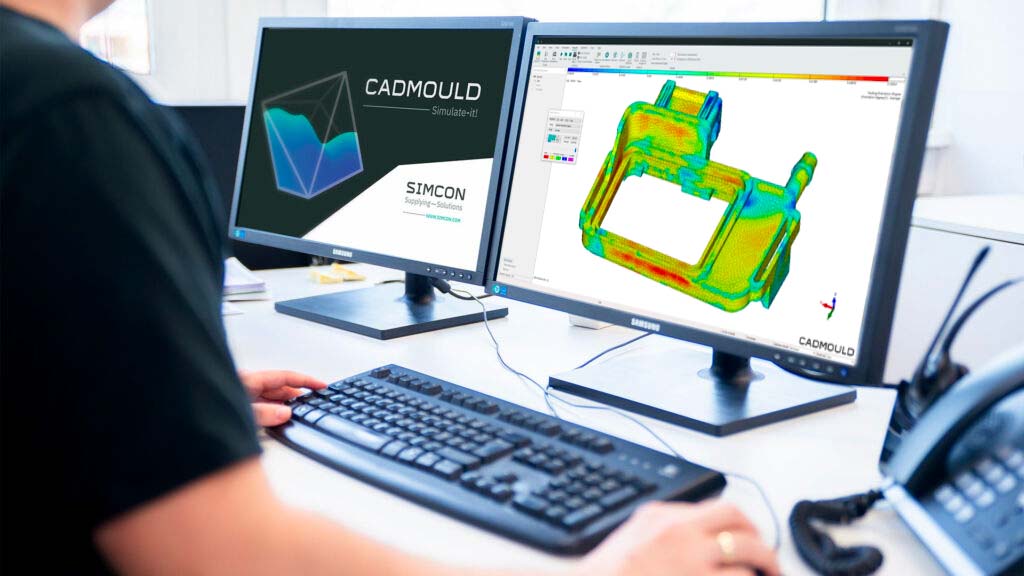

Paperless parameter transfer from simulation to the injection molding machine is crucial, if injection molders want better results.

1 min read

Fast series production with significantly reduced warpage. This was the result of PLASTON and GOLLMER Formen working together to refine the mold design of the innovative hybrid adapter plate.

Warpage was one of the biggest problems, because dimensional accuracy was the most important criterion for this component, which is intended to make various transport boxes combinable with each other. German mold maker Gollmer Formen helped refine the mold design so that it could be mass produced quickly and with significantly reduced warpage.

In the whitepaper "One adapter to stack them all" you can read the approach of each step and how SIMCON's software solutions CADMOULD and VARIMOS were used along the way.

Paperless parameter transfer from simulation to the injection molding machine is crucial, if injection molders want better results.

1. Use The Right Material And Not Too Much Of It! Which material you choose has a significant impact on your costs. The material you initially select...

Find out what the advantages and disadvantages of plastic injection molding simulation are. Our opinion: if the prerequisites are right, it only...