Tear down this wall: ARBURG and SIMCON connect simulation and machine

Paperless parameter transfer from simulation to the injection molding machine is crucial, if injection molders want better results.

1 min read

Bi-directional communication between the simulation and the machine makes it easier for engineering and the shop floor to collaborate effectively.

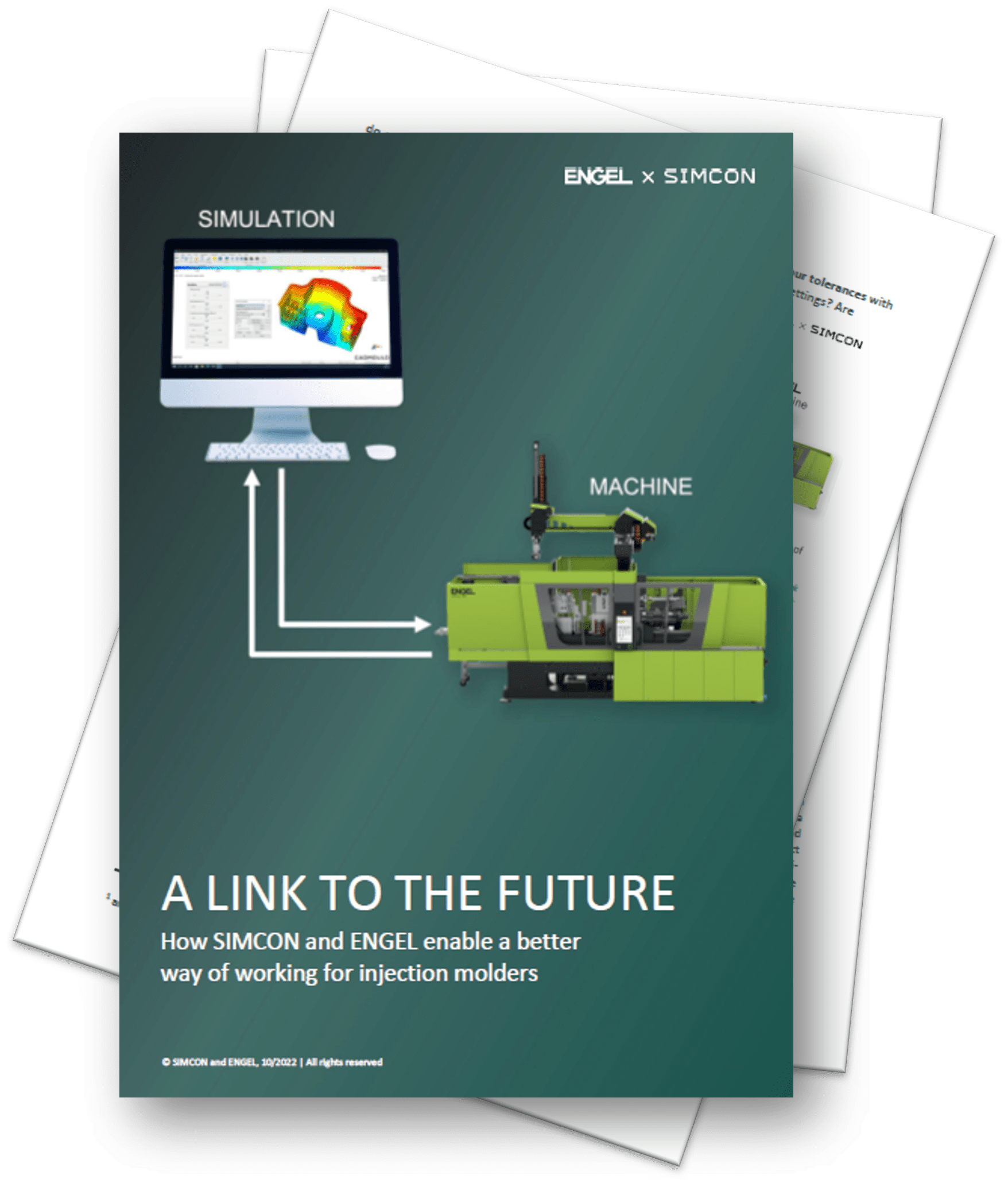

There are clear advantages to transferring data digitally from plastic injection molding simulation to the machine. By introducing bi-directional communication between the simulation and the machine, ENGEL and SIMCON make it easier for engineering and the shop floor to collaborate effectively.

Parameters can be optimized in advance, in parallel to the design of the part and mold geometry. By incorporating the wisdom of experienced machine setters already at the virtual stage of design, engineering can ensure that the combination of geometry and parameters has a higher likelihood of success.

The likelihood of costly physical mold corrections is reduced, accelerating time to market. By transferring pre-optimized settings digitally to the machine, the settings are mapped correctly and effortlessly to the machine controls. During tryouts, machine operators will give the settings some final real-world optimization to achieve optimal results.

By digitally relaying these changed settings back to the simulation software used in engineering, it gets easier for engineering to learn from any remaining errors and ensure that they are not repeated in future projects.

In the whitepaper, ENGEL and SIMCON describe this better way of working.

Paperless parameter transfer from simulation to the injection molding machine is crucial, if injection molders want better results.

3 min read

Shanghai, People’s Republic of China, March 18, 2021 Simulation and optimization solutions now available at ZIMMY, China Digital engineering...

Koorean CAD/CAM specialist INCOS INC is now distributing SIMCON’s plastic injection molding simulation and optimization software CADMOULD and VARIMOS.