FREE ONLINE WEBINAR

How to Achieve Unparalleled Process and Planning Reliability in Molding

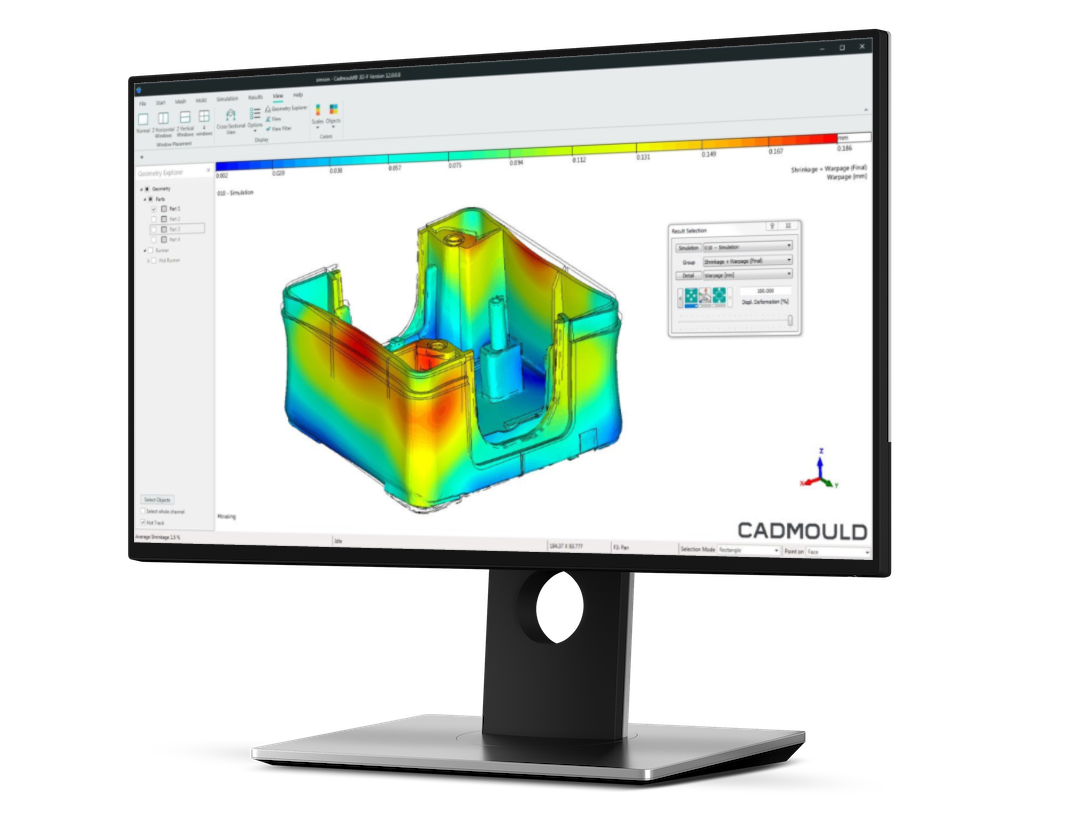

Explore the transformative power of injection molding simulation with CADMOULD, VARIMOS, and T-Box module in our exclusive webinar, tailored for professionals seeking to leverage advanced simulation in their product development and quality management processes.

Are you still viewing injection molding simulation as a niche for tech-savvy engineers? Think again. Our upcoming webinar unveils how early-stage simulations are not just a boon for product developers, but a financial game-changer when collaborating with toolmakers. Discover how to make your development-to-production transition seamless, ensuring your first production run meets quality standards effortlessly.

Join us to learn how to turn what seems like wishful thinking into a practical, competitive edge for your company. This webinar includes:

- Live Q&A Session: Directly engage with our experts.

- Real Component Demonstrations: See CADMOULD, VARIMOS, and T-Box in action.

Topics at a Glance

Discover transformative strategies and insights to enhance your product development and injection molding processes.

- Improve planning, procurement and quality assurance processes with CADMOULD, VARIMOS and T-Box

- Create and use digital twins early in the product development process

- Understand material and process parameters and enhance standard simulations with additional edge conditions

- Design simulation-based specifications for toolmakers to make the transition from development to production efficient

- Clarify specifications and reliably carry out cost and quality assessments based on simulation results

- Plan components in line with plastics and achieve set quality standards from the very first shot

Meet Your Hosts

Join industry veterans Michael Oppermann and Angela Kriescher in an insightful webinar that goes beyond the basics of plastic injection molding.

Michael Oppermann

Head of Simulation, Keller Engineering

With over 20 years in plastic injection molding, Michael Oppermann excels in simulation, expert analyses, and technology opinions. At SIMMO and Keller Engineering, he leverages CADMOULD and VARIMOS to guide clients in creating accurate digital twins, streamlining development, and hastening series production.

Angela Kriescher

SIMCON

Angela Kriescher brings 15+ years of experience in transforming customer insights into innovative solutions. Her journey from application engineer to product leader is marked by her in-depth involvement in evolving CADMOULD, ensuring it meets the dynamic needs of the industry.

Frequently Asked Questions

-

Who should attend this webinar?

This webinar is highly recommended for professionals who have a strong connection to plastics technology and injection molding. It's particularly beneficial for product developers, heads of product development departments, engineers in plastics production, and quality management professionals. If you are involved in the automotive, aerospace, or chemical industries, or if you develop products but do not produce them yourself, this webinar will be especially relevant and insightful for you.

-

How do I log in to the webinar?

Once you have registered for the webinar using the form on this website, you will receive a confirmation email with all the necessary details. This email will also contain a direct link to join the webinar. Simply click on the link at the scheduled time to participate.

-

I've registered but haven't received an invitation yet. Did I do something wrong?

No need to worry! To comply with regulations, we must verify that the email address you provided is indeed yours. This is done through a double opt-in process. If you've previously registered for a webinar or subscribed to our newsletter, you're already confirmed. If not, please look for a double opt-in email in your inbox and click the button within to confirm your address. Once confirmed, your invitation will be promptly sent. If you can't find the email, kindly check your spam folder or contact us for assistance.

-

Will I be able to get a copy of the slides presented in the webinar?

Yes, absolutely. We will share the presentation slides with all registered attendees after the webinar. This way, you can review the material at your own pace and refer back to key points as needed.

-

What technical requirements are needed to attend the webinar?

To ensure a smooth experience, please ensure you have a stable internet connection and a compatible browser. We recommend using the latest version of Google Chrome, Microsoft Edge, Firefox, or Safari. No special software is required; the webinar can be accessed directly through your browser.

-

Can I ask questions during the webinar?

Absolutely! We encourage active participation. There will be a live Q&A session where you can submit your questions, and our experts will do their best to answer them.

-

Can I contact the presenter after the webinar for follow-up questions?

Yes, contact details of the presenters will be shared during the webinar, and you are welcome to reach out to them for any further queries or clarifications.

-

Is the webinar available in multiple languages?

The webinar will be conducted in German at 10:00 and in English at 14:00 (GMT +1:00). Please register for the session that best suits your language preference.

Simulation Makes the Difference

In the dynamic world of plastic injection molding, staying ahead means embracing cutting-edge tools and methodologies. Here are four good reasons why injection molding simulation is a real game changer for you too.

Anticipate and Resolve Problems Early

Simulate the entire molding process before physical tool construction begins. Understand what will happen inside the mold and why, allowing you to preemptively address potential issues. This proactive approach not only saves time but also prevents costly errors.

Experiment with Solutions Virtually

Test multiple design and process solutions in a virtual environment without the need to construct a physical mold. Virtualizing tool corrections ensures you get it right the first time, saving significant time and resources.

Optimize Production for Peak Efficiency

Use simulations to find the most efficient solution beyond mere error prevention. Improve cycle times and reduce material and energy consumption. This not only protects the environment, but also has a positive impact on your budget.

Accelerated Time-to-Market with Advanced Simulations

Say goodbye to the slow and often frustrating trial-and-error method. Achieve better results faster by testing multiple solutions concurrently. This positively impacts your budget, making your operations more cost-effective than ever.