VARIMOS bootcamp Generate, Simulate, Analyze, Optimize

Upgrade your way of working: learn to automate variant analysis with VARIMOS!

Learn to use automated variant analysis!

VARIMOS is a new way of working in plastic injection molding part, mold and injection parameter design. It offers powerful automations for generating, simulating and analyzing multiple variants of your original design quickly and efficiently, and for finding an optimal solution.

Our VARIMOS Bootcamp will get you up and running with this new way of working! You'll learn to set up a variant analysis, run the simulations, analyze results across simulations, and find the best solution interactively!

VARIMOS is a better way of working. It automates generating, simulating, analyzing and optimizing variants of your design, to help you find a better solution, faster.

Get a 4-week VARIMOS trial license

Get a 4-week unrestricted trial version of VARIMOS for 99 EUR!

If you complete the bootcamp successfully, you have the option to get an unrestricted 4-week license for VARIMOS at a trial price of 99 EUR. That way, you can try the software on your own projects. During the trial period, you will have full access to our support.

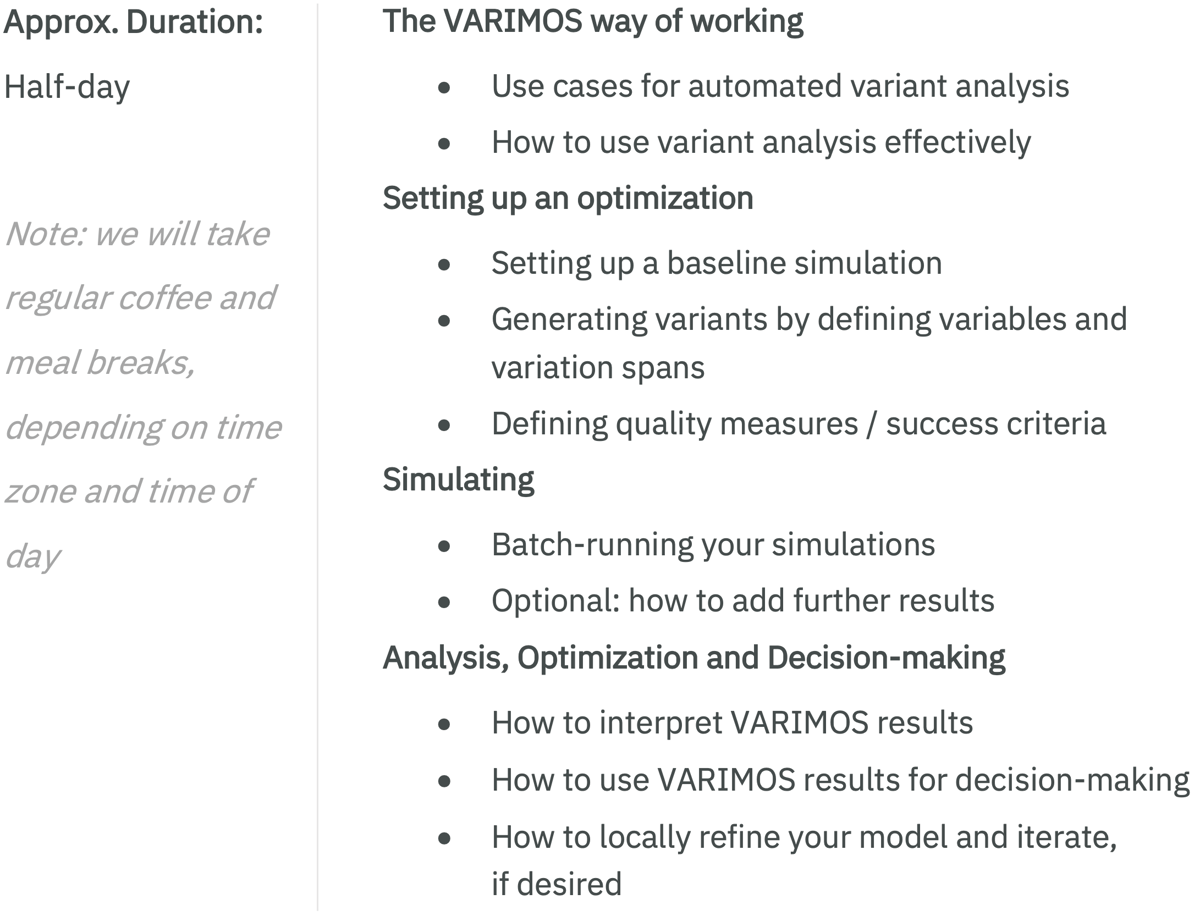

Bootcamp contents:

What you will learn in a VARIMOS Automated Variant Analysis Bootcamp

In our automated variant analysis bootcamp, we'll use examples to introduce you the VARIMOS workflow end to end. After completing the bootcamp, you'll know what you need to launch your own projects, using VARIMOS!

- Use cases for VARIMOS

Here we will discuss what kinds of questions are suitable for VARIMOS analysis, and why. Example questions that can be tackled include

- How can I optimize injection parameters?

- How can I use an injection parameter variation to argue that geometric changes are necessary?

- How can I minimize shrinkage and warpage, by varying local wall thicknesses?

- How can I reduce weld lines by optimizing the flow path, using wall thickness variation?

- How to set up a VARIMOS variant analysis:

Here you will learn how to generate variants, by defining a list of variables. Essentially, you tell VARIMOS what to vary and by how much, and it will translate that into a set of simulations to run, to learn about the effect of these variables. You'll also learn how to tell VARIMOS what to optimize, by specifying quality measures, i.e. success criteria and their tolerances. - How to interpret results and use them to make decisions

We will go through a few concrete part examples, and show how they can be analyzed and optimized efficiently with VARIMOS. We’ll deep-dive on how to interpret the simulation results, and how to decide what to do next.

VARIMOS helps you paralellize your design process. Generate, simulate, analyze and optimize design variants rapidly and using automated support. Spend less time on tedious repetitive steps and free up capacity for results interpretation and decision-making!

Why automate variant analysis?

The "good-old-fashioned" way of working during part and mold design involved lots of trial and error. You simulate your first design, look at the results, discover some issues, generate ideas on how to fix them, change your design, simulate again, rinse and repeat.

This is already a much better way of working than physical trial and error after you build your mold, because virtual changes are much faster and cheaper than real-world changes. But it's still a slow process, because you're simulating and analyzing alternatives one by one.

VARIMOS is a much faster, more parallel and more efficient way of systematically generating, simulating and analyzing variants of your design, and finding the best solution quicker. It automates a lot of the repetitive, tedious work of iterating. Once you've used VARIMOS you'll be surprised you ever worked without it!

BENEFITS FROM USING VARIMOS

- Find better solutions, faster

by automating tedious repetitive steps in your design process - Prove whether you need to modify geometry, or whether parameter modifications are enough. If the optimal result you get using only parameters as your variables is not good enough, then that proves that you will need to change something else than parameters -- i.e. modify part or mold geometry, or use a different material.

- Further reduce the number of mold corrections relative to "standard" simulation, because you'll find better solutions

- Collaborate better with your colleagues and customers, because VARIMOS suggestions are not a black box. You'll be able to explain your rationale based on our interactive results!