1. Set goals

You define your goals and which quality measures you want to optimize.

VARIMOS is an automation layer that sits on top of our simulation software CADMOULD. Its automations help you to quickly generate many design variants, simulate them hyper-efficiently, and analyze results from multiple simulations in a summarized fashion. Powerful artificial intelligence helps you by suggesting optimal solutions, based on your targets!

If you're still simulating "the good old fashioned" way, you're iterating manually. In this old way of working, you create a design, simulate, look at the results, change something, simulate again, etc. It's a repetitive process.

VARIMOS automates the repetitive parts of this process. It enables you to quickly set up many design variants, simulate them in parallel, and analyze the results using artificial intelligence.

VARIMOS doesn't just present you with a single black-box "optimum" solution. Rather, it makes a suggestion, and then you can play around, change variable settings and see what would change, if you did it differently.

Simply change the variable sliders on the left, and instantly see what will happen to your results, on the right. The results update in real-time. No need to run more simulations and wait!

Sensitivity answers the question: How do the variables influence the goals or quality measures? You can interactively vary the variables with simple sliders and immediately see what changes in the results . This allows you to see at first glance which variables are most important and which have only a minor influence on your results.

VARIMOS finds an optimal suggestion for improving component, tool and process parameters in order to optimally achieve your goals. Mathematically.

This complex automotive tail light initially had warpage issues. This made it impossible to laser-weld together the front and back of the case.

We used VARIMOS automation to find a better solution that successfully minimized shrinkage and warpage.

The laser-welding succeeded and the customer won an award for their innovative engineering solutions.

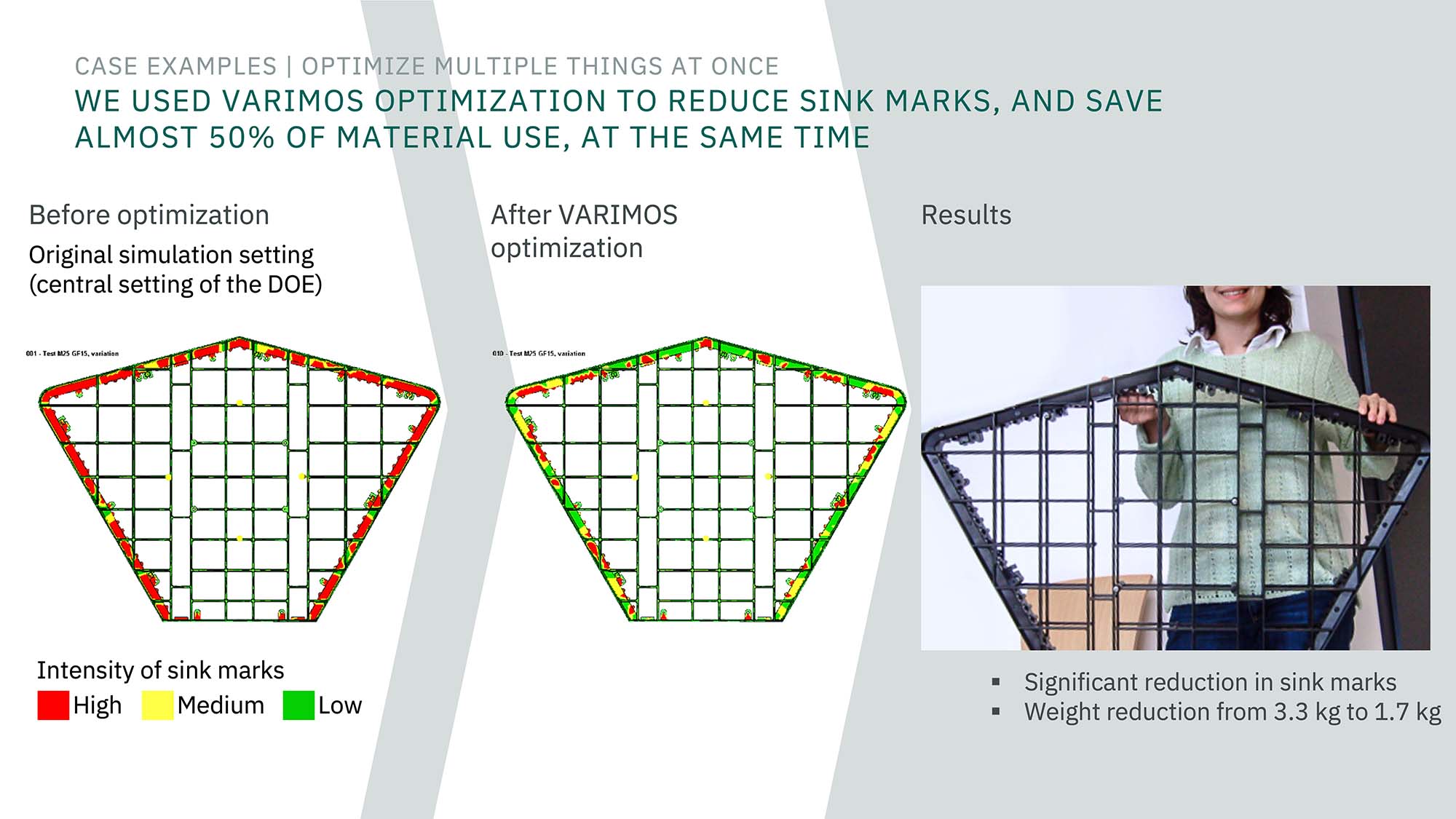

This industrial filter case had significant sink marks, as you can see on the left-side picture.

VARIMOS was used to find ways to fix this issue, while also reducing weight.

The result was significantly reduced sink marks, with simultaneously reduced part weight!

The good news is: it's super simple. All you need to do is three things: define goals, define your variables, and get results!

You define your goals and which quality measures you want to optimize.

You then tell VARIMOS which variables and parameters it may change and what restrictions it must not violate.

Based on your answers, VARIMOS will create a Design Of Experiments for you, automatically run these experiments as simulations, create a meta model from the results, and visualize the results for you, simply and interactively.

VARIMOS supports a more modern, digitalized way of working in plastic injection molding design. Automate tedious repetitive tasks. Focus on real value-added work, creative problem-solving and collaborative decision-making.

If you want to read more about this better way of working, check out our whitepaper (Co-authored with our friends at Volume Graphics!).

Frequently asked questions and answers about VARIMOS

In VARIMOS, you can vary variables that are continuous, and that have a continuous response. For example, this can be

Such variables can be varied in a reasonable range around an initial value. If you make your variations too drastic in magnitude, you may change the behavior so drastically that it will be difficult to model.

There are also variables that VARIMOS can not yet automatically vary, because they are categorical in nature, such as

Most users find that they do not need to purchase new hardware to run VARIMOS effectively. They just use the same computer that they use to run their regular simulations.

To harness the full power of parallelization, we recommend a fast 64-Bit multicore CPU,

such as AMD Ryzen 5xxx Serie, Intel Core i5, i7, i9, or Xeon of the most recent generation, with a clock speed of at least 4 GHz, ideally with 8 or more Cores / 16 Threads.

For full details, refer to our systems requirements!

Foundationally, you need to know how to use CADMOULD. Building on this, there are dedicated VARIMOS bootcamp trainings to get you started with your first optimizations, which take a half to full day, to get you started.

Even after you complete your initial training, our support is of course ready to help you with the evolving challenges in your daily work.

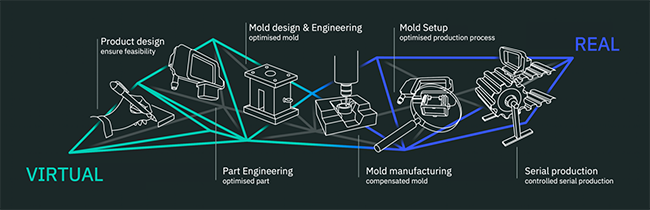

VARIMOS can be used in the VIRTUAL variant. Here, the design of experiments is executed in simulation, as described above.

VARIMOS can also be used in the REAL variant. In this case the experimental design is not simulated, but physically carried out on the machine. This is suitable for optimizing the process parameters for existing tools or parts that are already in production, or to optimize the set-up process for new molds.