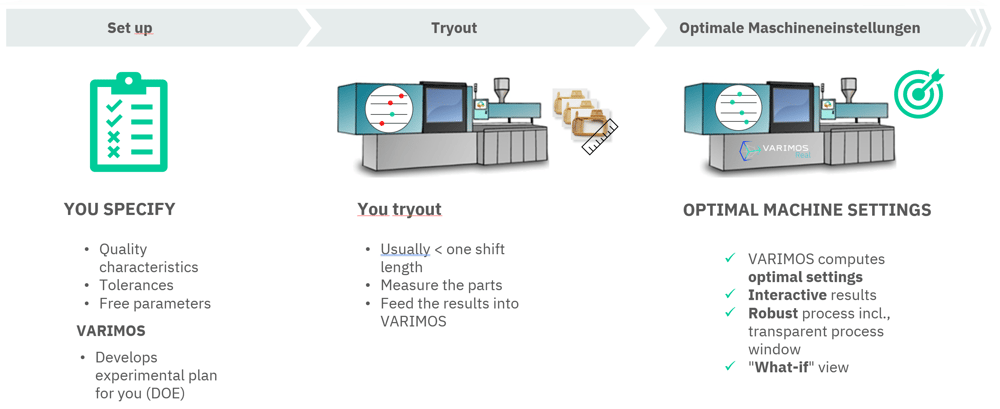

EFFICIENT TRYOUT PLAN

Reliably find the best possible settings and assess feasibility, with the smallest possible number of trials.

VARIMOS Real enables machine setters to get the most out of their molds. Troubleshoot molds with issues. Find the optimal machine settings for new molds. Get conclusive evidence whether a mold corrections is inevitable. And do it all in a single shift.

Who has the time to test all possible combinations of machine settings? Injection pressure profiles, temperature control, clamping forces, etc., influence the result, and countless possible combinations exist.

VARIMOS Real creates a reliable design of experiments (DOE) for you and predicts how the part quality will respond to different machine settings.

Based on the available data, it even predicts the quality for settings that you did not try.

Your advantage: You run a fixed number of trials, but you still learn about all possible combinations of settings.

Your results are safe and reliable after a single shift.

Reliably find the best possible settings and assess feasibility, with the smallest possible number of trials.

Determine within one shift whether you can solve your problem with machine settings. Or whether a mold correction is inevitable.

Don't block your machines for longer than necessart. You'll know the total number of trials needed even before you begin sampling. So you can plan your time better.

Determine the largest possible process window within which all specifications are reliably met.

Instant preview of what would happen if you changed machine settings.

Show your colleagues, customers, and management why your settings are better than any alternative. Conclusively, and simply.

VARIMOS Real will answer the following questions:

Based on the results of your tryouts, VARIMOS Real predicts what will happen at any combination of machine settings. You can change the machine settings virtually, and immediately see what happens.

Just move the sliders for the machine settings on the left, and you get an instant prediction what will happen to your part quality, on the right.

How will different settings influence the part quality?

It's simple!

TRYOUT:

OPTIMAL MACHINE SETTINGS:

This includes, for example...

You can analyze any part quality feature, whether they are measured or entered manually.

The systems requirements for VARIMOS Real are moderate. Most regular Intel or AMD CPU (x86 architecture) laptops and office computers will do.

Any current Intel or AMD x86 architecture CPU running Windows 10 or later will do. Older operating systems going back to Windows 8 also work, but since they are no longer provided with security updates by Microsoft, we don't recommend that you use them.

Regarding hardware, you do not need the same kind of computational horse-power that you need for running simulations. This is because VARIMOS Real uses real-world measurements and not simulations as its data.

We offer dedicated trainings for first-time users, online or in person. Usually it will take you about one workday in total, split into two sessions.

Usually we do the trainings in two parts: half a day to learn how to set up your tryouts using VARIMOS Real, and then a second half day to interpret results, after you have run the tryouts.

Of course, if you run into challenges later on, your subscription fee also includes SIMCON support to help you solve them.